T: +86-182-2202-9592

E: yuantai@yuantai-steel.com

E: yuantai@yuantai-steel.com

No.1 Science and Technology Road, DaQiuZhuang Industrial Zone, Jinghai, Tianjin, China 301606

| Availability: | |

|---|---|

| Quantity: | |

Zinc aluminum magnesium coated steel pipe is a type of steel pipe that has been coated with an alloy of zinc, aluminum, and magnesium.The coating is a ternary alloy with zinc as the main

component, and the content of aluminum and magnesium ranges from 1.5% to 8%, with the magnesium content not less than 0.2%.

Categories | square steel pipe |

Brand | Yuantai Derun Steel Pipe Manufacturing Group |

Model | hfw-square tube near me |

Thickness | 0.5- 60mm |

OD(Outer diameter) | 10*10-1000*1000mm |

Certification | CE,LEED,BV,PHD&EPD,BC1,EN 10210,EN10219,ISO9000 |

Surface Treatment | Black painted or REQUEST |

Tolerance | as required |

Length | 0.5-24m according to client requirement |

Standards | Hollow section: ASTM A500/A501,EN10219,EN10210 |

Materials | S355J2H |

Delivery Time | 7-30 Days |

FOB port | Tianjin port |

Product Specification

There are some standard sizes that we can produce.We also can produce non-standard sizes and can be customized by your requirements,please contact us.

Product Display

Zinc Aluminum Magnesium steel pipe

ZAM coating steel pipe stock

Zinc aluminum magnesium coated steel pipe is a type of steel pipe that has been coated with an alloy of zinc, aluminum, and magnesium.The coating is a ternary alloy with zinc as the main

component, and the content of aluminum and magnesium ranges from 1.5% to 8%, with the magnesium content not less than 0.2%.

Categories | square steel pipe |

Brand | Yuantai Derun Steel Pipe Manufacturing Group |

Model | hfw-square tube near me |

Thickness | 0.5- 60mm |

OD(Outer diameter) | 10*10-1000*1000mm |

Certification | CE,LEED,BV,PHD&EPD,BC1,EN 10210,EN10219,ISO9000 |

Surface Treatment | Black painted or REQUEST |

Tolerance | as required |

Length | 0.5-24m according to client requirement |

Standards | Hollow section: ASTM A500/A501,EN10219,EN10210 |

Materials | S355J2H |

Delivery Time | 7-30 Days |

FOB port | Tianjin port |

Product Specification

There are some standard sizes that we can produce.We also can produce non-standard sizes and can be customized by your requirements,please contact us.

Product Display

Zinc Aluminum Magnesium steel pipe

ZAM coating steel pipe stock

Strict Product Inspection

Direct reading spectrometer

Hardness tester

Large impact experimental enquopment

YUANTAI DERUN STEEL PIPE MANUFACTURER GROUP attaches great importance to R&D and quality control.Because strict quality control is the great guarantee,R&D and innovation of products is the basic task of enterprises of the brand.We usually do mechanical property,metallography testing,chemical composition analysis,plating coating testing,diemension measurement,non-destrucive testing.

The steel pipe manufacturing raw materials of the company come from HBIS,Shougang,Baotou Steel,Xintiangang,Rongcheng steel,Jinxi steel and other large-scale well-known steel manufacturing enterpries in China.

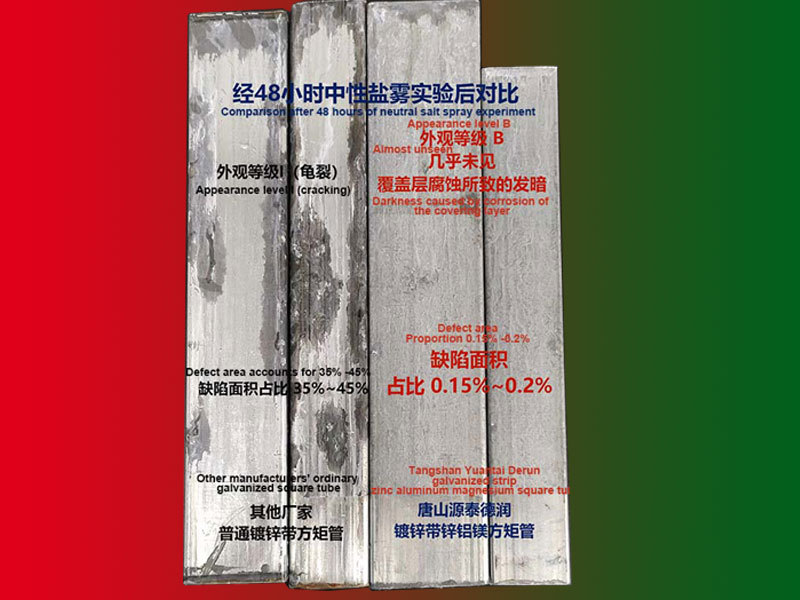

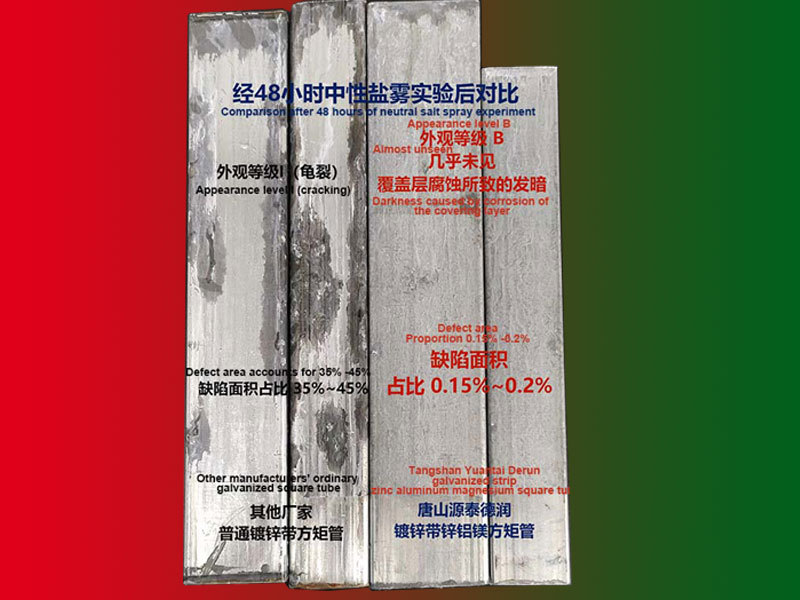

Our ZAM steel pipe VS Other steel pipe

Through the years, "perfection" has been the only goal we pursue.

In order to satisfy customers, with continuous efforts, we are working towards perfection through a quality assurance system, which has given us the ISO 9001,ISO 14001,ISO 45001,CE,ABS,DNV,JIS and others.

Our pipe mill high frequency straight line welding pipes and has an annual output ability of 10 million tons.

Certification

Strict Product Inspection

Direct reading spectrometer

Hardness tester

Large impact experimental enquopment

YUANTAI DERUN STEEL PIPE MANUFACTURER GROUP attaches great importance to R&D and quality control.Because strict quality control is the great guarantee,R&D and innovation of products is the basic task of enterprises of the brand.We usually do mechanical property,metallography testing,chemical composition analysis,plating coating testing,diemension measurement,non-destrucive testing.

The steel pipe manufacturing raw materials of the company come from HBIS,Shougang,Baotou Steel,Xintiangang,Rongcheng steel,Jinxi steel and other large-scale well-known steel manufacturing enterpries in China.

Our ZAM steel pipe VS Other steel pipe

Through the years, "perfection" has been the only goal we pursue.

In order to satisfy customers, with continuous efforts, we are working towards perfection through a quality assurance system, which has given us the ISO 9001,ISO 14001,ISO 45001,CE,ABS,DNV,JIS and others.

Our pipe mill high frequency straight line welding pipes and has an annual output ability of 10 million tons.

Certification

Our Zinc-Aluminum-Magnesium (Zn-Al-Mg) square and rectangular tubes feature an advanced coating that significantly boosts resistance to environmental degradation, ensuring a longer service life.

These tubes are crformance. The Zn-Al-Mg alloy provides a strong yet flexible framework for various construction and engineering applications.

Our Zn-Al-Mg tubes are an environmentally conscious choice, combining recyclability with a reduced need for maintenance. This contributes to a lower lifecycle cost and a smaller environmental footprint.

Aesthetic Appeal and Versatility in Design

Aesthetic Appeal and Versatility in Design It can be used in architectural and decorative applications where both the functionality and the visual aspect are important. The pipes can be easily fabricated and shaped into different forms, enabling designers to create unique and aesthetically pleasing structures. For example, in modern architecture, ZAM steel pipes can be used as handrails, balustrades, or decorative columns, adding a modern and durable touch to the building design.

Our Zinc-Aluminum-Magnesium (Zn-Al-Mg) square and rectangular tubes feature an advanced coating that significantly boosts resistance to environmental degradation, ensuring a longer service life.

These tubes are crformance. The Zn-Al-Mg alloy provides a strong yet flexible framework for various construction and engineering applications.

Our Zn-Al-Mg tubes are an environmentally conscious choice, combining recyclability with a reduced need for maintenance. This contributes to a lower lifecycle cost and a smaller environmental footprint.

Aesthetic Appeal and Versatility in Design

Aesthetic Appeal and Versatility in Design It can be used in architectural and decorative applications where both the functionality and the visual aspect are important. The pipes can be easily fabricated and shaped into different forms, enabling designers to create unique and aesthetically pleasing structures. For example, in modern architecture, ZAM steel pipes can be used as handrails, balustrades, or decorative columns, adding a modern and durable touch to the building design.

ZAM steel pipes are used to construct roofs and wall panels, providing long-term protection against corrosion, especially in harsh outdoor environments. Their resistance to rust and weathering helps maintain the integrity and appearance of buildings over time.

In building structures, ZAM steel pipes can be used for columns, beams, and other load-bearing elements. Their high strength and corrosion resistance ensure the stability and durability of the structure, reducing the need for frequent maintenance and replacement.

The good formability and strength of ZAM steel pipes make them suitable for scaffolding systems. They can withstand the weight of workers and construction materials while being resistant to corrosion caused by exposure to the elements during construction projects.

ZAM-coated steel pipes are used in the manufacturing of vehicle chassis and underbody components due to their excellent corrosion resistance. This helps protect the vehicle's structure from rust and corrosion, increasing its service life and maintaining its safety and performance characteristics.

The high-temperature resistance and corrosion resistance of ZAM steel make it suitable for use in exhaust pipes and related components. It can withstand the corrosive effects of exhaust gases and the high temperatures generated during engine operation, ensuring the reliability and durability of the exhaust system.

Some body parts of automobiles, such as door frames, pillars, and bumper reinforcements, can also be made of ZAM steel pipes. This provides enhanced protection against corrosion, especially in areas prone to salt spray or other corrosive substances on the road, improving the overall quality and longevity of the vehicle.

ZAM steel pipes are used to construct roofs and wall panels, providing long-term protection against corrosion, especially in harsh outdoor environments. Their resistance to rust and weathering helps maintain the integrity and appearance of buildings over time.

In building structures, ZAM steel pipes can be used for columns, beams, and other load-bearing elements. Their high strength and corrosion resistance ensure the stability and durability of the structure, reducing the need for frequent maintenance and replacement.

The good formability and strength of ZAM steel pipes make them suitable for scaffolding systems. They can withstand the weight of workers and construction materials while being resistant to corrosion caused by exposure to the elements during construction projects.

ZAM-coated steel pipes are used in the manufacturing of vehicle chassis and underbody components due to their excellent corrosion resistance. This helps protect the vehicle's structure from rust and corrosion, increasing its service life and maintaining its safety and performance characteristics.

The high-temperature resistance and corrosion resistance of ZAM steel make it suitable for use in exhaust pipes and related components. It can withstand the corrosive effects of exhaust gases and the high temperatures generated during engine operation, ensuring the reliability and durability of the exhaust system.

Some body parts of automobiles, such as door frames, pillars, and bumper reinforcements, can also be made of ZAM steel pipes. This provides enhanced protection against corrosion, especially in areas prone to salt spray or other corrosive substances on the road, improving the overall quality and longevity of the vehicle.